Often modelers of rubber powered free flight airplanes try to get the maximum amount of turns into the rubber strand motor but at the risk of breaking the rubber. By using a torque meter modelers can determine how close their motor is likely to break.

A small rubber test motor of the same rubber stock is prepared the same as the real motor and wound up until it breaks. All this time the meter is used to determine at what torque point the rubber got to before bursting. When the real motor is wound up the modeler now knows how close it can come to the breaking limit.

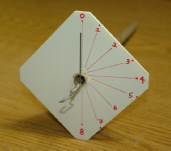

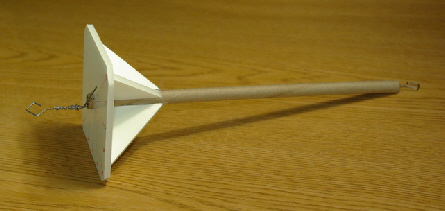

This meter works by twisting a metal wire that runs the entire length of the meter. One end of the wire is securely fixed to the tube. This tube has a dial on one end and as the inner wire twists the indication needle moves along the dial.

This meter was made with rolled brown construction paper, .047” music wire, solder and wire, and foam board for the dial.

Torque Meter for winding

rubber motors

An excellent book to learn the intricacies of rubber models

“Rubber Powered Model Airplanes”

by Don Ross

Dial made from foam board

Solidly fixed wire end